Project Management

Strategies for Effective PI

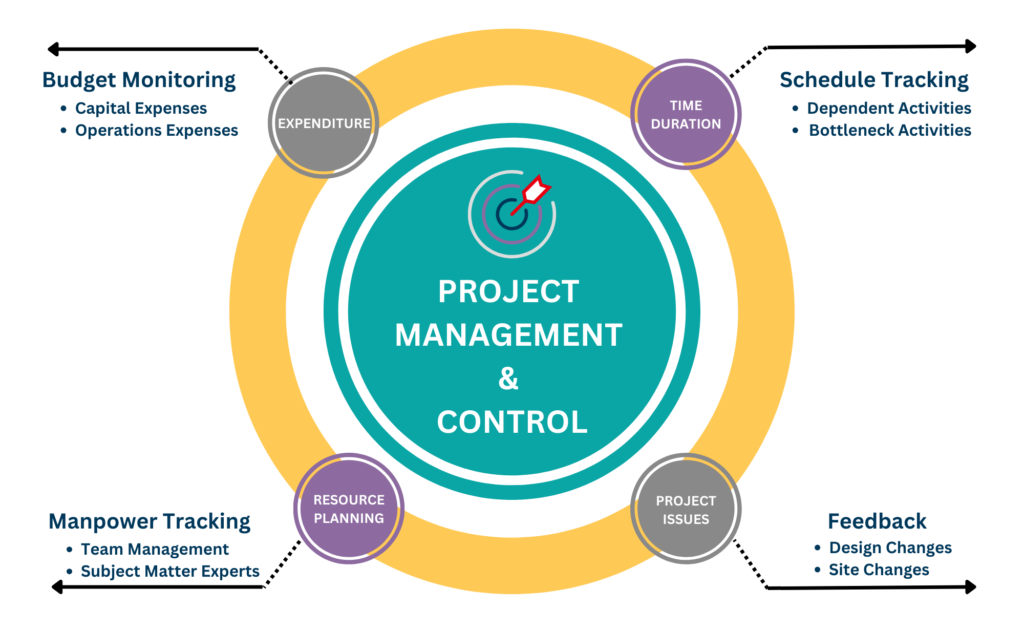

A facility’s success vastly relies on the project management capacities. Clean and Control are experts at reducing the turnaround time of project execution without deviating from set standards. All credit to our unique project management philosophy & set controls.

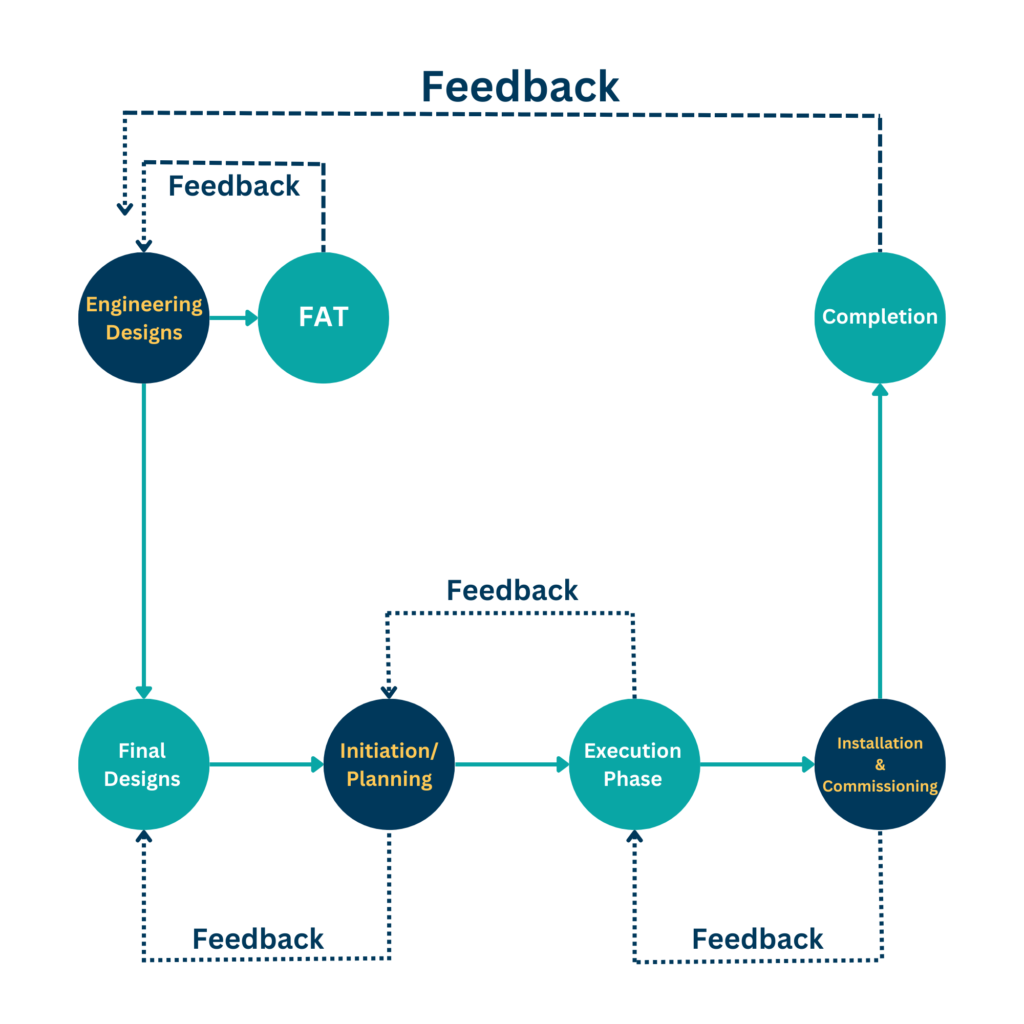

At Clean and Control, we prioritize the centralization of project management, which guarantees every stakeholder has access to accurate information at any given time. For successful project implementation & progress validation, we spare no effort. Our pharmaceutical project management approach begins with capturing data from the start through to completion. With systematic feedback, stakeholders can perform real-time analysis and corrective measures can be implemented to limit any potential delays.

Our key project management and control services include:

- MSP project scheduling

- Quality check, assurance and control

- Factory acceptance test (FAT)

- Realtime feedback from site installation team

- Agile methodology for faster curative action

- Data recording and management

- Project documentation

- Resource planning and documentation readiness

We ensure better control of projects by working alongside our customers through all stages of the project lifecycle. Our back-office experts assist clients as well as staff to effectively handle documentation during customs clearance and project commissioning. With our front and back-end support, clients can ensure smooth operation of departments that aid in quickening up project execution. Our unique approach to project management has enabled us to become sought-after worldwide as GMP consultants. We strive not only for timely project completion but also to identify choke points before they become an issue while implementing effective processes and procedures. Clean and Control’s philosophy provides various outstanding benefits such as:

- Quality assurances and checks periodically.

- A shorter turnaround time leading to a boost in ROI.

- Seamless data flow across diverse channels & partners.

- Early discovery of bottlenecks.

- Better expenses & resources management.

- Right planning and workflow visibility.

- Less rework due to real-time data sharing.

- Tested and verified integration systems.

- Access to all technical data in one place.

- Single point of contact for all pharma needs.

- Management data approach protocols.

- Innovative & adaptive strategies.

From Vision to Execution